How Steel Homes combine manufacturing and construction to create 21st century efficiency

DfMA- how Steel Homes combine manufacturing and construction to create 21st century efficiency

Although manufacturing and construction appear to be very different, there are striking similarities. For example, BMW design components of car engines that share common characteristics across a range. These are then assembled in factories, using processes that can be repeated. The end-product of this is produced in one place, using people with specific skills, by utilising technology and automation.

On the other hand, construction is the total opposite. It uses materials that are brought in from a diverse supply chain, then assembled in differing conditions, geographies and environments. The end-product can take years to complete, often built by an unskilled workforce that results in varying degrees of quality.

The processes are clearly different, but the end-product is where the similarity lie. As the demand for buildings such as affordable homes increase, so does the expectation for speed, quality consistency and cost assurance. Compare a car coming off the production line with a house in a residential development, they both look just like the one made before and after them.

DfMA then, might be the answer to construct high-quality, standardised, efficient buildings, that are built to a time restricted programme and strict budget. By removing the uncertainty of low skills, bad weather, poor material quality, Steel Homes offers a solution for the construction industry to make it more efficient and cost effective while resolving the housing problem the UK so desperately needs.

Other industries such as aerospace and automotive use smarter processes that we are adopting at Steel Homes. Construction offers unique challenges and opportunities that allow us to pioneer change through modern methods.

At Steel Homes we are rethinking the way we design, engineer and construct. We believe that construction must break the traditional mould so that we can build safer, more sustainably, quicker and to a higher quality. We are building certainty into our processes just as BMW does in its factories. We want to streamline it so that value is added throughout the whole process which ensures the end user does not pay for the inefficiencies of everyone in the chain of production.

FORTEK

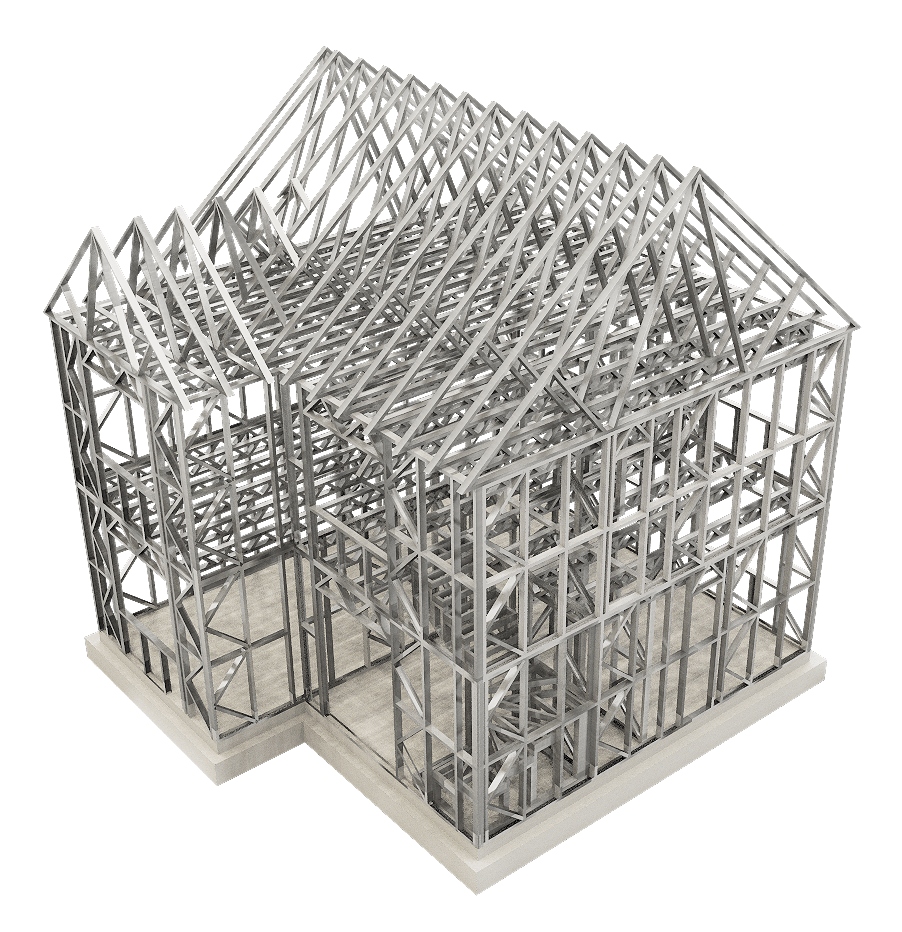

DfMA has been made possible through FORTEK, our own digital engineering and manufacturing facility, that often produces complex building systems in factory conditions that they can be assembled prior to delivery to a construction site for installation.

By harnessing the power and flexibility of FORTEK into everything we offer, we have bridged the gap between manufacturing and construction, creating 21st century efficiency for the UK Housing market.

“By far, the most important benefit is safety. By removing construction from site to a controlled factory environment, risks have been mitigated by eliminating hazards. This has a lasting positive impact on health and safety.” Emrah Coskun